Leading LED Technology Since 2009

Focus on custom wavelength from 250nm to 1600nm with 2016, 2835, 3528, 3535, 3030, 5050, 6868, 7070 and 9090 package, 0.2W to 500W High Power LED for Medical, Industrial, Defense, Aerospace, Surveilance, Scientific and other versatile applications.

Contact UsAbout Lumixtar

With over 16 years of experience in LED technological packaging, we are dedicated to providing innovative lighting solutions.

Your Trusted LED Partner

Since 2009, Lumixtar is driving light innovation with transformative illumination solutions. We focus on providing custom and special wavelength LEDs that offer superior reliability, long-lasting performance and a distinct competitive advantage. Our commitment is to empower our customers through advanced, tailored light technologies.

We could design, customize and develop a comprehensive portfolio of LED for UV Disinfection, UV Curing, Medical Instrument, Red Therapy Light, Horticulture, Defense, Aerospace, Industrial Use and other professional applications.

Our mission is to deliver products through rigorous quality control and commitment to custom-designed solutions to ensure and address our clients' most cirtical needs.

Learn More

Our Product

We have a comprehensive portfolio of led components for versatile application.

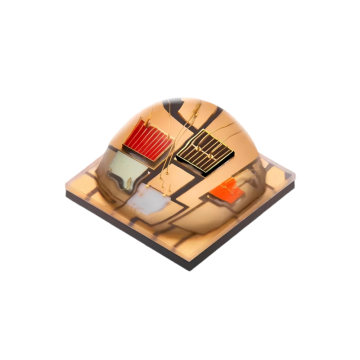

SMD LED and High Power LED

Covering 0.2W to 500W with a broad 250-1650nm wavelength spectrum, including versatile SMD options.

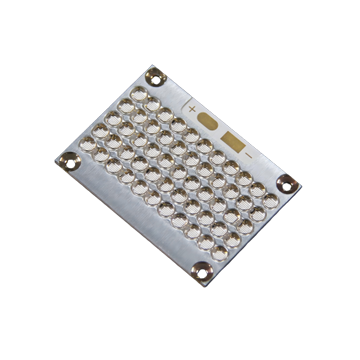

Read MoreCustom LED Solutions

Custom LEDs products engineered to meet any specific requiremnt for wavelength and power.

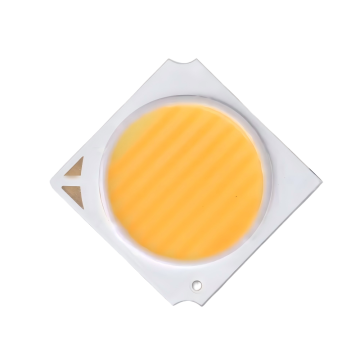

Read MoreHigh CRI COB LEDs

Sunlight full spectrum with high CRI>95, our LEDs are precisely tuned to cover wavelength from 365nm to 1050nm.

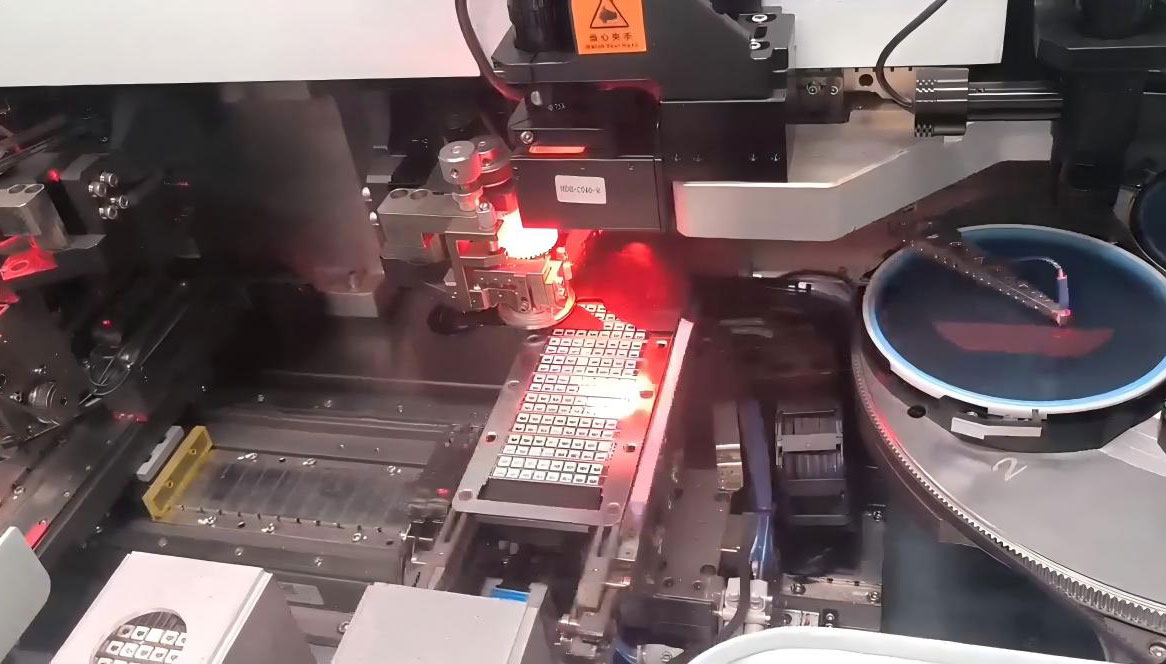

Read MoreOur Factory

State-of-the-art manufacturing facilities with advanced equipment and strict quality control.

Precision Production Process

Every LED is crafted through a meticulous, multi-stage process to ensure superior performance and reliability.

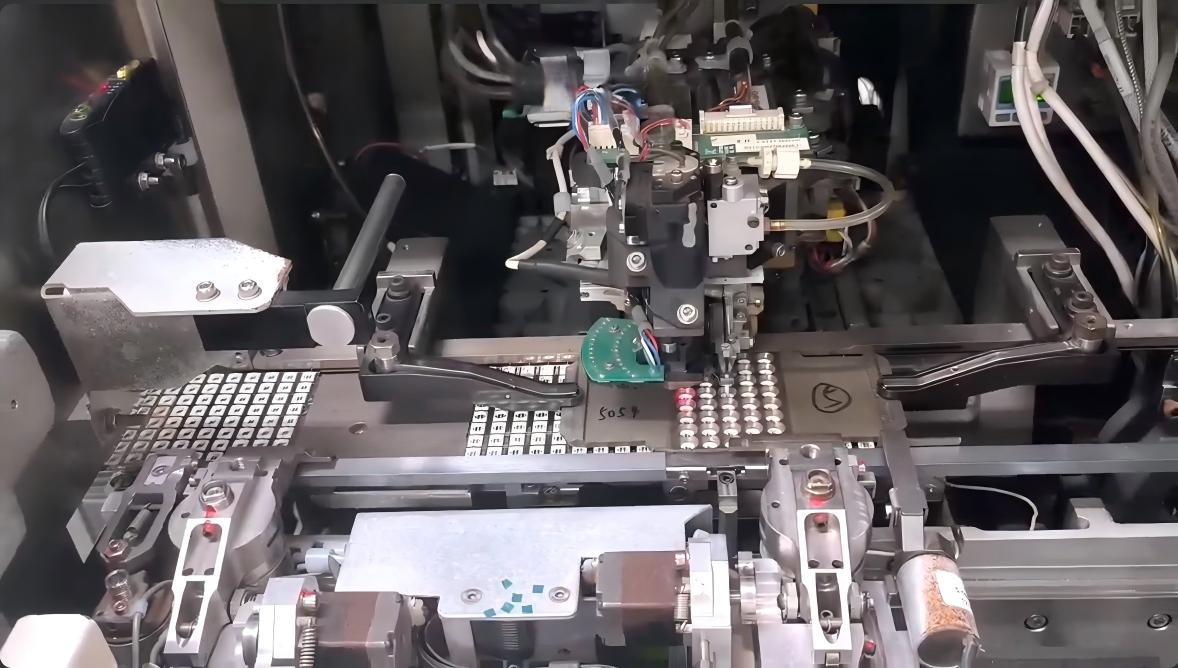

Step 1: Die Bonding

Using automated die-attach equipment, the LED chips are precisely placed and bonded into the substrate or package lead frame with high-thermal-conductivity solder.

Step 2: Wire Bonding

99.99% Pure gold wires are used to create stable electrical connections between the chip and the package terminals. This critical step is monitored for consistency and strength to ensure long-term stability.

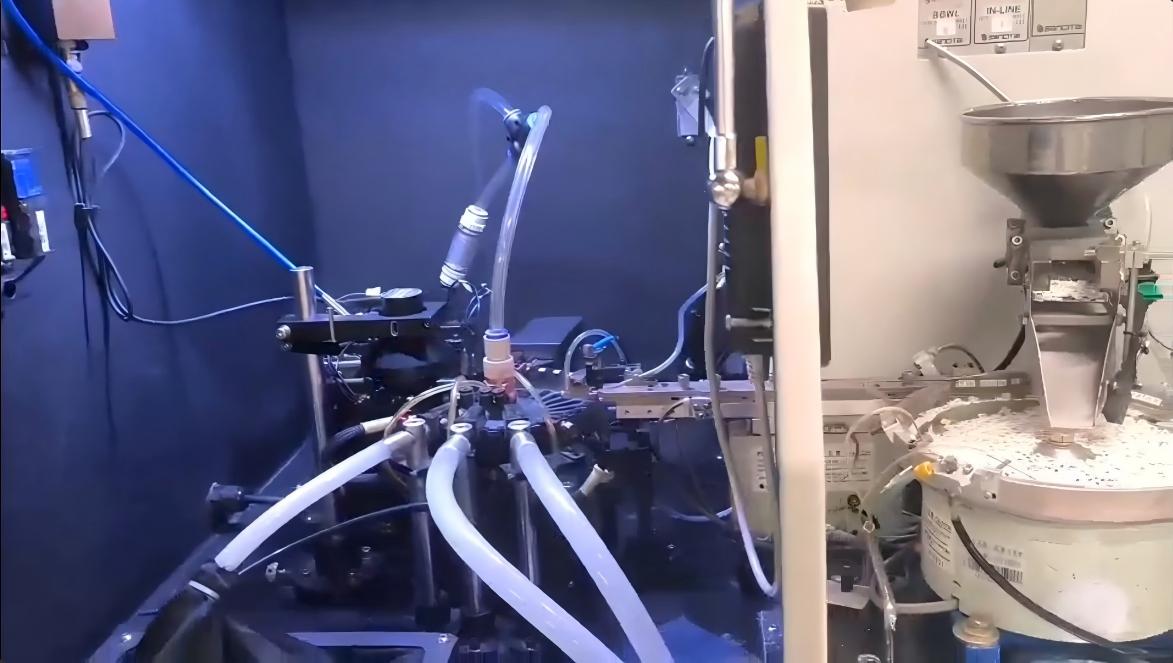

Step 3: Molding and Dispensing

The silcone and phosphor mixture is precisely placed into LED package on the top of the LED chip. This coating defines the final color and protects the LED from physical and environmental damage.

Step 4: Oven Baking

LEDs are cured in a controlled oven. The thermal process hardens the encapsulant, ensuring its long-term structural integrity, optical properties, and overall reliability.

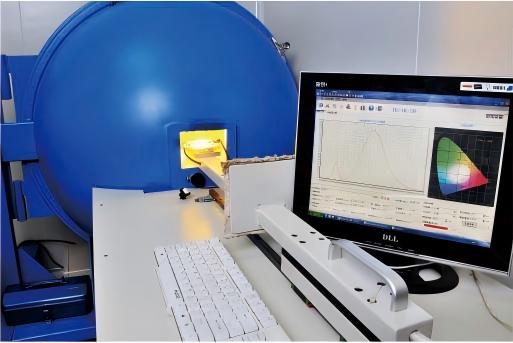

Step 5: Bining and Taping

LEDs are measured for key parameters like the lumen output and the color. They are sorted into performance bins and reeled into tape for efficient handling and automated assembly.

Step 6: Quality Control

A final sampling audit tests electrical performance and reliability to make sure the entire batch meets all specifications, ensuring consistent, higFeah-quality product before shipment.

Our Advantages

Why customers choose LUMIXTAR for their LED solutions.

Industry Leadership

With over 15 years of expertise and trusted by 1000+ global clients, we deliver proven LED solutions worldwide.

Production Excellence

State-of-the-art manufacturing facilities ensuring reliable supply, fast delivery, and exceptional quality standards.

Custom Solutions

Technical support and custom LED solutions to meet your specific application requirements.

Our Equipment

Advanced machinery and testing equipment to ensure the highest quality standards.

Our Partner

Ready to Illuminate Your Projects?

Contact us today to discuss your LED requirements and discover how LUMIXTAR can provide the perfect lighting solution for your application.

Get In Touch