Food Safety Inspection & Contaminant Detection

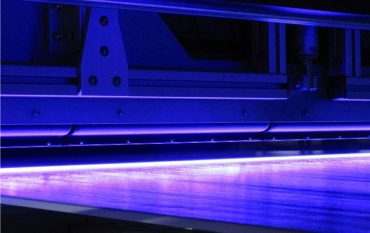

Lumixtar food inspection LED systems enhance food safety by revealing contaminants, spoilage, and foreign materials invisible to standard vision. Our specialized UV (365nm) and NIR (850nm to 940nm) lighting solutions enable detection of plastic, glass, bone fragments, and organic residues on high-speed production lines.

These LED systems integrate with machine vision cameras to identify defects at rates up to 10,000 items per minute. The IP69K-rated housings withstand high-pressure washdowns, while the uniform illumination eliminates shadows that could hide contaminants in meat, poultry, seafood, and produce processing.

Critical food safety applications:

- Foreign object detection in packaged foods

- Bruise and defect identification in fruits

- Bone fragment detection in poultry processing

- Mold and spoilage recognition in grains

- Package seal integrity verification

Technical specifications:

Reduce recall risks and ensure consumer safety with Lumixtar’s food inspection LED solutions. Request a free lighting analysis for your production line.